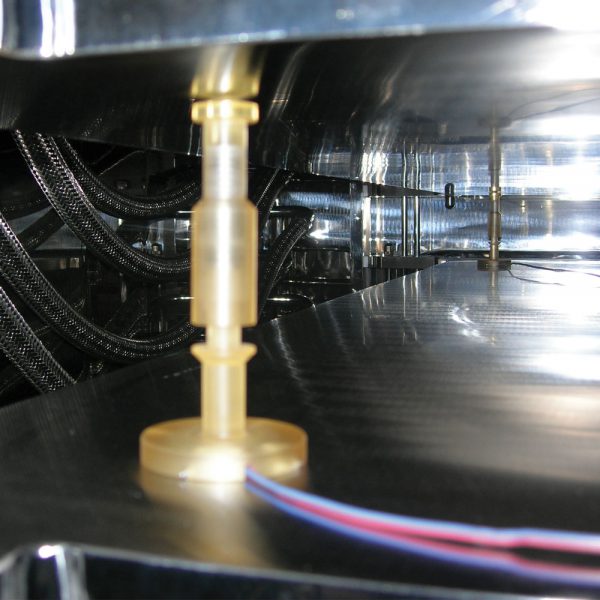

- GL Engineering’s Thermocouple Clamping System is uniquely designed to improve the measurement accuracy of thermocouples for critical monitoring and qualification test applications in lyophilizer systems. Errors in this area are typically associated with thermocouple placement and contact along with the use of adhesives and heat transfer paste when setting up temperature uniformity studies in lyophilizer shelves.

- Eliminates the mess, reduces the hazard, and minimizes measurement error using an innovative solution to maintain constant contact and provide consistent heat transfer under extreme temperature pressure/vacuum conditions.

973-740-0001 info@gl-engineering.com

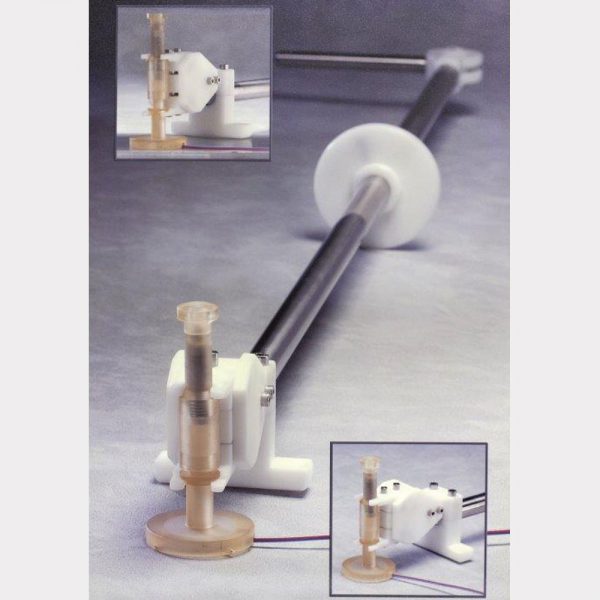

THERMOCOUPLE CLAMPING SYSTEM

Features

Key Advantages

- Operates in a wide range of temperatures and pressures (Full vacuum to 2 Bar pressure and -80°C to +130°C)

- Utilizes an advanced polymer housing that is resistant to extreme environmental stresses

- Integrates a compressible clamp and placement tool to provide rapid, safe and repeatable thermocouple placement

- Safe: Eliminates the need to reach into a chamber or between shelves by utilizing an easy to use placement tool

- Accurate: Attain temperature variations of less than 0.350°C between thermocouples

- Residue-free: Test your system without heat transfer paste or adhesives that require time-consuming cleanup

- Efficient: Set-up and remove thermocouples in less than half the time required with manual systems

- Versatile: Test your lyophilizer under full vacuum and low temperatures or high pressure and high temperature conditions with the same system

- Reliable: Secure your thermocouples with uniform holding pressure without lifting during testing

- Precise: Place your thermocouples in the same location each time with guides provided on the placement tool

- Repeatable: Eliminate error and variability associated with operator thermocouple preparations and placement