For many years, GL Engineering has been providing startup, commissioning, FAT, SAT, engineering and qualification services, as well as validation documentation to the Aseptic Processing Pharmaceutical Industry.

973-740-0001 info@gl-engineering.com

PHARMACEUTICAL ENGINEERING SERVICES

Before

After

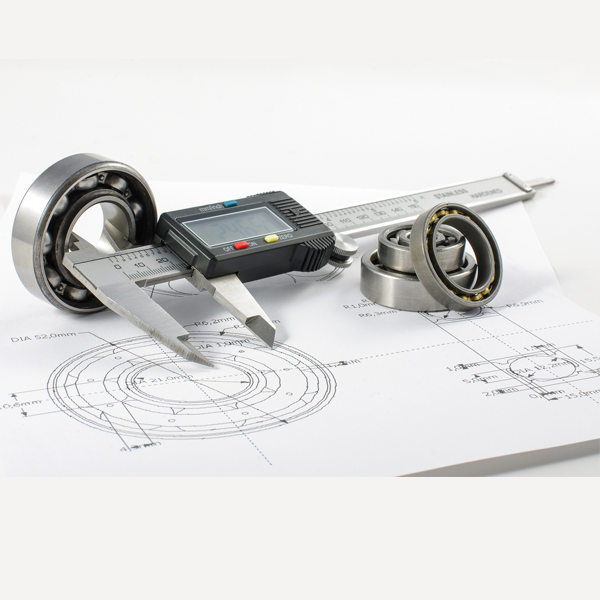

Design

- The process begins with a discovery meeting to uncover any problems the customer has dealt with in their current (or new) system, what they hope to achieve with the customized products/services and how GL Engineering can help the customer accomplish their goals in the cleanest, simplest way possible.

- Next, GL Engineering’s team will draw up the designs and concepts to solve the issues presented by the customer.

- GL Engineering handles all aspects of developing the product / process design and implementation.

Prototyping

- Once the designs are approved, GL Engineering will then create a prototype based on the concepts and materials chosen by the customer.

Quality Assurance

- Prototypes are strenuously tested with fluids and simulated operations to ensure systems and components fit properly with the necessary machinery and equipment.

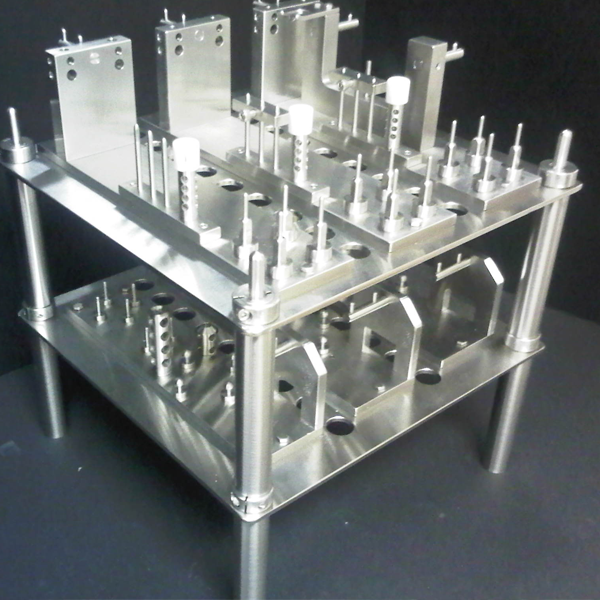

In-House Manufacturing

- GL Engineering’s in-house manufacturing process allows for full discretion over all materials and methods used throughout the procedure.

Cleanroom Environment

- GL Engineering ‘s cleanroom is designed to meet and exceeds ISO 7 (Class 10,000) specifications, providing a controlled environment with HEPA-filtered air containing a low number of particulates during the assembly and packaging process.

Packaging

- GL Engineering’s filling needles can be packaged with a block and snap guard to preserve the integrity of the needles during transport, handling and sterilization.

Support Services

GL Engineering offers a full range of support for our products and systems including:

- Operator training (against a structured training protocol)

- Comparative Test Protocol

- Full-service factory qualification and validation testing available

Consulting

- GL Engineering offers consulting services to companies needing machinery recommendations, revamping or creating new single-use filling needle systems, needle design and product prototyping, as well as validation and qualification services for Aseptic Processes.