GL Engineering’s Custom-Designed Single-Use Filling Needles

973-740-0001 info@gl-engineering.com

Filling Needles

- Cost-effective and unique alternative to conventional, reusable filling needles

- GL Engineering has both ready-made options along with bespoke needle designs and fitting systems

- Our filling needles and systems can be made to suit all varieties of needle holders and filling machines and are easily integrated into new or existing filling operations

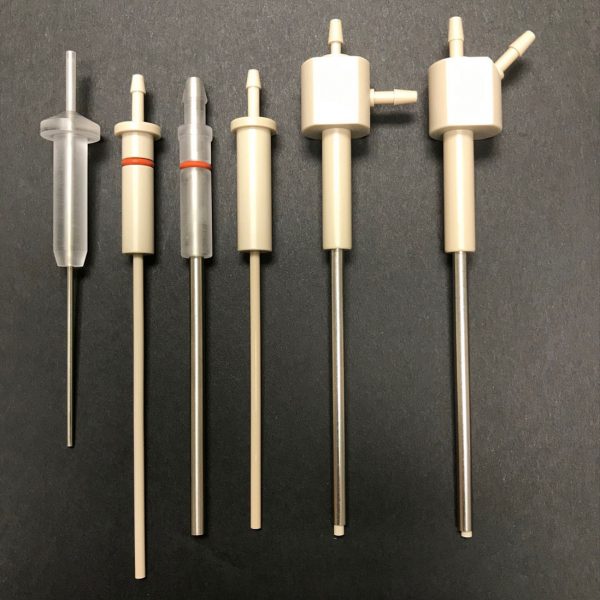

- Materials of needle construction typically include 316L stainless steel tubing, custom-designed polycarbonate housing, or as customer specified

- In addition to conventional filling needles, Co‐Axial Filling Needles enable the filling of gas overlay liquid products without replacing the current filling equipment. The 2nd port on the Co‐Axial Filling Needles allows for simultaneous gas addition as the liquid product at the same filling station..

- Needle housing can be standard or friction-fit (with silicone O-ring)

- GL Engineering will fit the needle holder to any brand of filling machinery

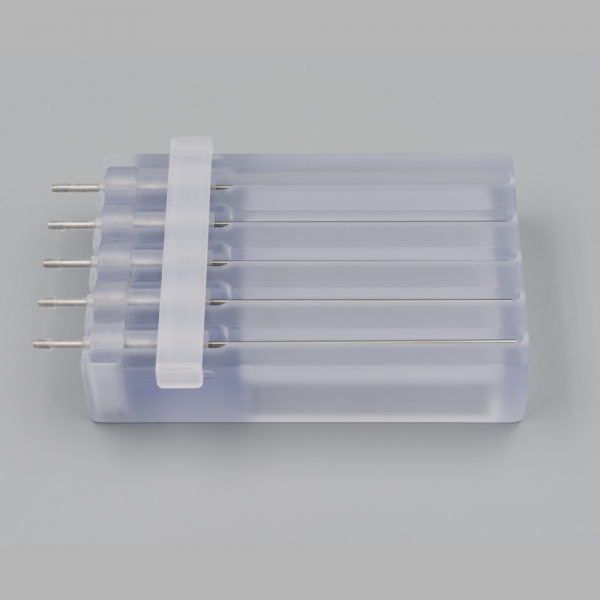

- Needles can be protected with block and snap guard packaging to preserve integrity

- Our in-house manufacturing process uses no oils or adhesives

- Needle straightness and overall concentricity are routinely inspected

- Critical dimensions are verified prior to lot-release